Our Story, Nestled in the Gaspereau Valley

Welcome to Little Foot Yurts!

We’re Alex and Selene Cole and we work and live in Mi’kma’ki, the traditional territory of the Mi’kmaq people.

As a small family business we specialize in handcrafted yurts for special events. Drawing inspiration from 3000-year-old traditions of the nomadic Kyrgyz people, we grow, harvest, and build our yurts using traditional techniques. Each yurt is a one-of-a-kind work of art, requiring special care in setup, takedown, and maintenance. Selene tailors the coverings, while Alex crafts the yurt frames and oversees our installation team.

Our fleet of unique shelters is small but has a mighty presence on the atmosphere of any wedding, festival or community event. Since 2005, we've been shaking up the tent game with our eco-friendly yurts!

The yurt is a collapsible circular framework of wooden poles used as far back as 3000 years by a horse riding nomadic nation of people through out Central Asia. Today it can still be found in use across the globe, from a cozy cabin, studio and gathering space. Its surprising strength, durability and the natural and sustainable way they are created is a testament to its ingenuity.

Burning holes into a steam bent ash wheel.

Alex Cole

Woodworking & Installation

Sewing a yurt wheel cover.

Selene Cole

Textiles & Client Bookings

How we got started

We met whilst traveling in Australia, and later moved to Wales to work on The Roundhouse Project, a traditional Celtic round house built with phragmites reed on the roof and earthen plaster on the walls.

This project was located in the Vale of Glamorgan in South Wales where we lived at Coed Hills Rural Artspace; and at the time was a not-for-profit co-operative social enterprise that promoted sustainable living and creative arts. Since then they have evolved into Coed Weddings, an incredible venue for weddings and art events.

It was at Coed Hills where we learned how to build yurts, along with tipis, log cabins and straw baled buildings in addition to the Iron Age Roundhouse.

Coed Hills allowed us to discover our passion about sustainable living, both ecologically and socially; the “unintentional community” that was formed at Coed Hills essentially became the catalyst for Little Foot Yurts. The amazing people and energy of Coed Hills changed our lives and inspired us to start a sustainable business. In 2003 we moved to Nova Scotia and in 2005 we started Little Foot Yurts.

Design & Production

We are builders of Nova Scotia coppice wood yurts, inspired by the traditional Kyrgyz and Mongolian style yurts.

-

Hand splitting, steam bending and using round wood produces a strong and unique frame.

Ancient building techniques such as hand splitting with a free, steam bending green wood and using tools such as a billhook produce a strong and unique yurt frame.

-

Coppicing, a traditional woodland management method, involves cutting trees to ground level, encouraging new shoots for future harvests and promoting sustainable wood production.

This age-old practice in Europe yields various wood products like firewood, fencing, and furniture.

Beyond the economic benefits, coppice development helps restore woodland health, especially after severe logging. This low-impact harvesting method enhances soil stability and ground-level habitats, contributing to increased biodiversity.

-

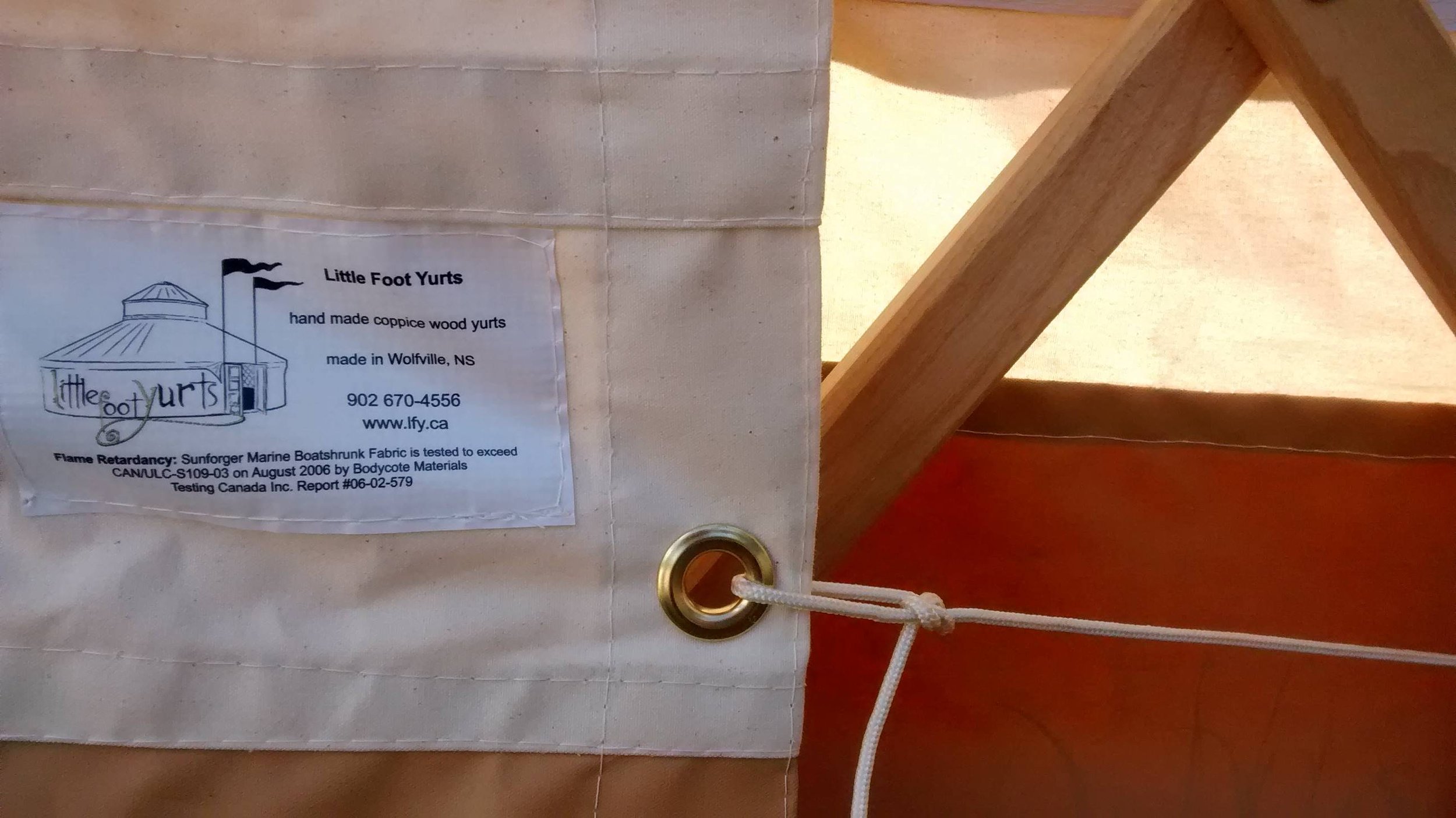

We are proud to use breathable natural membranes; cotton canvas and felt insulation. The benefits include significantly less condensation, no off gassing, more aesthetically pleasing, lighter, and easier to repair. Multiple layers of semi-permeable membranes ensures 100% weather protection.

Felt panels are the traditional yurt covering of Central Asia. Extremely durable and hard wearing they provide a natural, breathable insulation. The felt panels are enclosed by the cotton canvas to protect it from the weather.

-

Our yurts use the traditional central Asian design, which gives you one third more roof poles than modern style yurt companies.

Our yurts do not use complicated fixtures or fittings. The roof pole end fits into a burnt mortice hole and uses high quality locally made dacron rope for the loop on the opposite end.

Our Trip to Kyrgyzstan

In June of 2010, we travelled to Kyrgyzstan to immerse ourselves in yurt living, learning from felt artisans in textile design and yurt frame craftsmanship to deepen our cultural understanding. We hope you enjoy reading about our travels!